How to Choose the Right Hydraulic Baler for Your Waste Recycling Business

Selecting the perfect Waste Paper Hydraulic Baler Machine or other baling machine is a critical decision for any recycling operation. With the global push towards a circular economy and stricter waste management regulations, investing in efficient equipment like a hydraulic baler is no longer optional—it's essential for profitability and compliance. This guide will walk you through the key factors to consider, helping you make an informed choice that aligns with your business needs.

Why the Right Baler Matters

An efficient bale press machine can dramatically reduce storage space, lower transportation costs, and increase the value of your recyclables like cardboard, plastic, or metal. Whether you need a cardboard baler for a retail store or an industrial scrap metal baler for a junkyard, the right machine impacts your bottom line.

Step 1: Identify Your Primary Material

The type of waste you process is the most important factor. Different materials require different compression forces and chamber designs.

- Paper & Cardboard: For waste paper balers and cardboard box compactors, a standard horizontal or vertical baler with moderate pressure often suffices.

- Plastics: Plastic balers and PET bottle baling machines need to handle bulky, lightweight materials. Look for machines with high compression ratios.

- Agricultural & Biomass: Processing rice husk, straw, or wood shavings? Specialized rice husk balers, straw balers, and sawdust baler machines are designed to create dense, manageable bales for fuel or feed.

- Metals: Scrap metal balers, aluminium balers, and metal balers require extremely high pressure (often measured in tons) to compact dense materials.

- Textiles & MSW: Wiper rag balers and MSW balers for municipal solid waste need robust construction to handle mixed, sometimes abrasive materials.

NKBALER's Cardboard Box Baler Machine efficiently processes OCC for recycling.

Step 2: Determine Your Volume and Space

How much material do you process daily? A small vertical baler might be perfect for a supermarket, while a large-scale recycling plant needs a fully automatic horizontal hydraulic baler. Also, measure your available floor space. Vertical Balers have a smaller footprint, while horizontal balers require more room but offer higher output and automation.

Step 3: Consider Automation and Features

From manual to fully automatic, the level of automation affects labor costs and throughput.

- Manual/Semi-Automatic: Lower initial cost, suitable for lower-volume operations.

- Fully Automatic: Higher output, consistent bale quality, and reduced manual intervention. Ideal for plastic bottle balers or industrial cardboard balers in high-volume settings.

Look for features like programmable logic controllers (PLC), automatic wire-tying or strapping, and safety interlocks. Advanced systems, like the hydraulic servo system developed by NKBALER, offer precise control and energy savings.

A Semi-Automatic Horizontal Baler offers a balance of efficiency and cost.

Step 4: Evaluate Quality, Safety, and Support

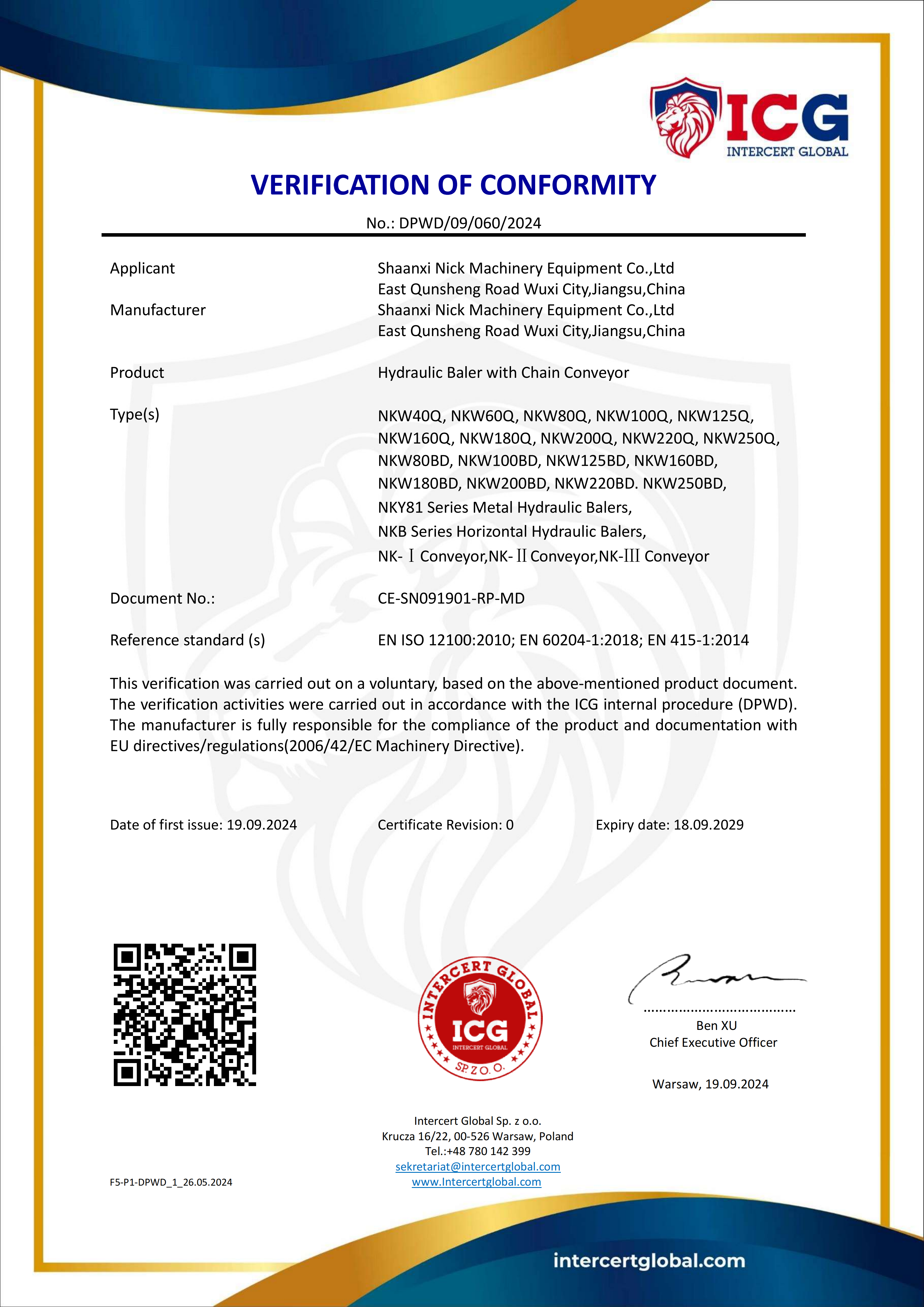

Never compromise on build quality and safety certifications. A reliable press compactor should be built with durable steel and feature safety guards. Key certifications to look for include:

- CE Certification: Essential for selling equipment in the European market, indicating compliance with health, safety, and environmental standards.

- ISO 9001: Demonstrates a consistent quality management system from the manufacturer.

For instance, NKBALER, with its 18 years of experience, holds both CE and ISO 9001 certifications, ensuring their hydraulic balers meet international standards. Their professional after-sales team provides crucial support for maintenance and spare parts.

Step 5: Think Long-Term: Total Cost of Ownership

The purchase price is just the beginning. Consider:

- Energy Consumption: An energy-efficient baling machine with a smart hydraulic system can save significant electricity costs over time.

- Maintenance & Downtime: Choose a supplier known for reliability and strong technical support. NKBALER boasts a dedicated team of over 20 after-sales service personnel.

- Versatility: Can the machine handle potential future waste streams? Some horizontal hydraulic balers can be adapted for multiple materials.

Why Consider NKBALER for Your Baling Solution?

As a leading Chinese manufacturer with nearly two decades of expertise, NKBALER offers a comprehensive range of hydraulic balers. Their product line includes specialized machines like rice husk bagging balers, alfalfa hay baling machines, silage baling presses, and textile clothes balers. Their independently developed energy-saving hydraulic system is a testament to their innovation, providing powerful compression while reducing operational costs. With exports to over 60 countries and a 99% customer satisfaction rate, they have established themselves as a trusted brand in waste recycling solutions.

For a detailed consultation on selecting the ideal Waste Paper Hydraulic Baler Machine, plastic baler, or any other baling press, visit their website or contact their expert team today.

Contact NKBALER:

Phone/WhatsApp: +8615021631102

Email: nk@nkbaler.com / Nickbaler888@gmail.com

Website: https://www.nkbaler.com

Address: East Qunsheng Road, Wuxi City, Jiangsu, China

Choosing the right hydraulic baler is an investment in the efficiency and sustainability of your business. By carefully assessing your material type, volume, space, and long-term needs, and partnering with a reputable manufacturer like NKBALER, you can ensure your recycling operation runs smoothly and profitably for years to come.