How to Choose the Right Hydraulic Baler for Your Waste Recycling Business: A Comprehensive Buyer's Guide

February 13, 2026 — In an era of growing environmental consciousness and stringent waste management regulations, investing in the right hydraulic baler is no longer a luxury but a necessity for businesses. Whether you're dealing with mountains of cardboard, streams of plastic bottles, or piles of metal scrap, a reliable baling machine can transform your waste handling from a cost center into a revenue stream. This guide will walk you through the critical factors to consider, helping you make an informed decision that boosts your operational efficiency and bottom line.

Understanding Your Waste Stream: The First Step

The most crucial step is to analyze the material you need to process. A waste paper hydraulic baler machine is optimized differently than a scrap metal baler. Here’s a quick breakdown:

- Paper & Cardboard: For cardboard balers and waste paper balers, you need consistent compression to create dense, uniform bales that maximize shipping weight and value.

- Plastics: Plastic balers and PET bottle baling machines must handle lightweight but voluminous materials. They often require specific chamber designs to prevent spring-back and create tight bales.

- Agricultural & Biomass: Materials like rice husk, wood shavings, and straw require specialized balers. A rice husk baler or sawdust baler machine might incorporate a bagging function, like a rice husk bagging baler, for direct packaging.

- Textiles & MSW: Wiper rag balers and Municipal Solid Waste (MSW) balers deal with mixed, often non-uniform materials, demanding robust construction and powerful hydraulic systems.

- Metals: Scrap metal balers, aluminium balers, and metal balers require immense pressure to deform and compact dense metal, necessitating heavy-duty frames and high-tonnage cylinders.

A robust Cardboard Box Baler Machine from NKBALER efficiently processes recyclable materials.

Key Selection Criteria for Your Baling Press

Once you've identified your primary material, evaluate these essential machine aspects:

1. Baler Type: Horizontal vs. Vertical

Horizontal Balers: Ideal for high-volume operations. They are typically larger, fully automatic or semi-automatic, and produce consistently sized, high-density bales. Perfect for large recycling centers, paper mills, and facilities with dedicated space.

Vertical Balers: Best for lower to medium volume. They have a smaller footprint, are often more affordable, and are suitable for retail stores, warehouses, and manufacturing plants where space is at a premium. NKBALER offers a range of both, including advanced semi-automatic horizontal balers.

NKBALER's Semi-Automatic Horizontal Baler offers a balance of automation and cost-effectiveness.

2. Hydraulic System & Pressure

The heart of any bale press machine is its hydraulic system. Look for energy-efficient systems that deliver high pressure for maximum density. For instance, NKBALER incorporates its independently developed hydraulic servo system and energy-saving hydraulic system in its high-density models. This technology ensures powerful compression while significantly reducing electricity consumption—a major operational cost saver.

3. Bale Size, Density, and Output

Match the machine's bale chamber dimensions and output capacity to your storage space, transportation logistics, and market requirements. Higher density bales fetch better prices from recyclers and reduce freight costs.

4. Automation Level & Safety Features

From manual tie-off to fully automatic wire-tying and bale ejection, the level of automation impacts labor requirements and throughput. Essential safety features include emergency stop buttons, two-hand operation controls, and safety gates.

5. Build Quality and Durability

A press compactor is a long-term investment. Look for heavy-duty steel construction, quality hydraulic components (like reputed pumps and valves), and robust welding. A manufacturer's experience is a good indicator. With 18 years of production experience, NKBALER builds machines designed for longevity in demanding environments.

Inside NKBALER's modern production workshop, ensuring rigorous quality control.

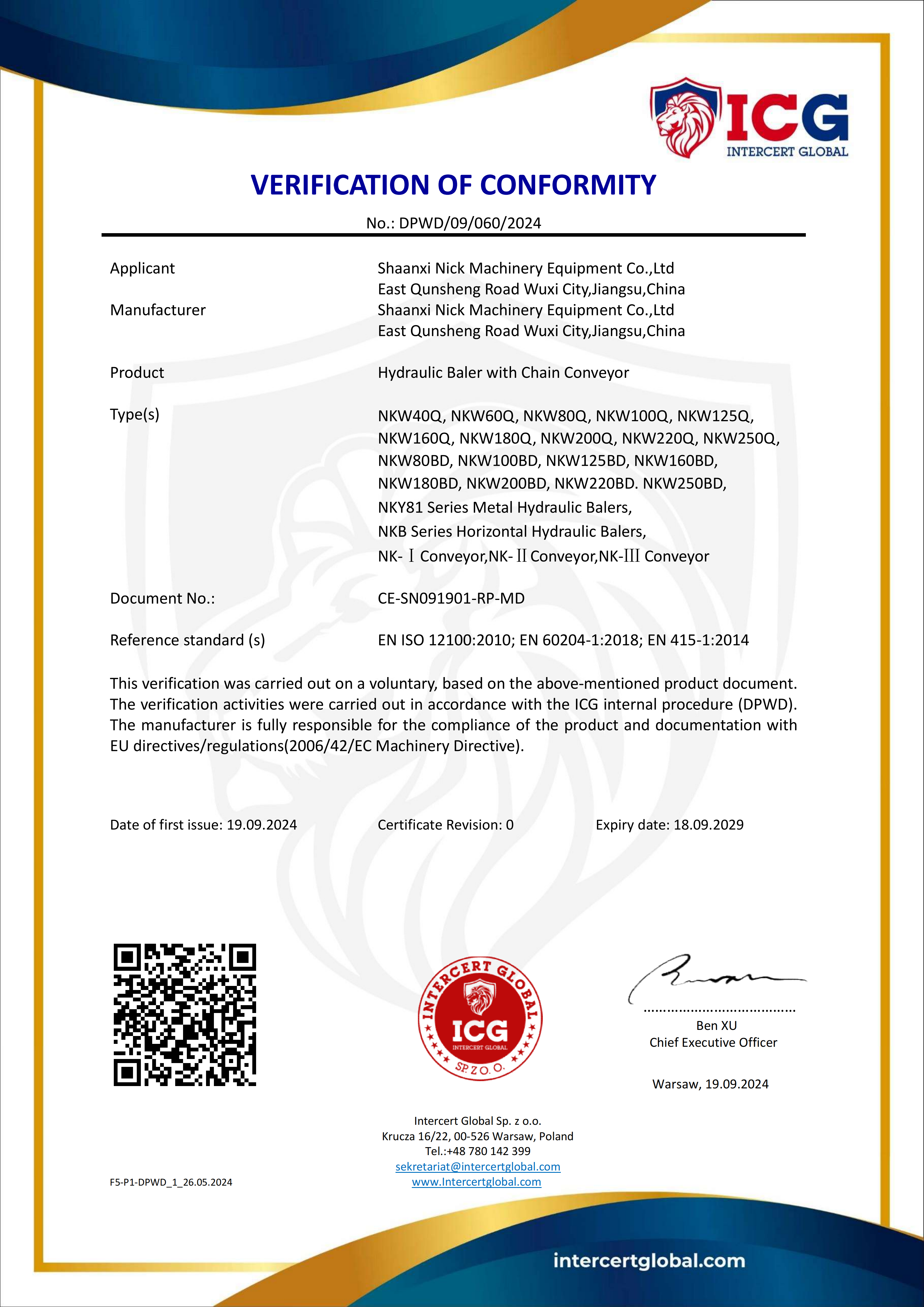

Why Certification and After-Sales Support Matter

Never overlook compliance and support. Machines should meet international safety standards. NKBALER products hold critical certifications like the CE certificate and ISO 9001 certification, which attest to their quality, safety, and reliability. These are not just badges; they are your assurance of a product built to global benchmarks.

Furthermore, comprehensive after-sales service is vital. A machine will need maintenance, occasional repairs, and spare parts. NKBALER backs its hydraulic balers with a dedicated team of over 20 after-sales service personnel, providing technical support, maintenance guidance, and prompt spare parts supply to ensure minimal downtime.

Industry Trend: The Push Towards Energy Efficiency and Smart Systems

The hydraulic baler industry is evolving. Recent trends highlight a strong move towards energy-saving technologies—exactly where NKBALER's servo systems excel. Additionally, integration with IoT for monitoring bale counts, machine health, and predictive maintenance is becoming more common, helping businesses optimize their recycling operations data-drivenly.

Making the Final Decision: Partner with a Specialist

Choosing the right baling machine—be it a plastic bottle baler, straw baler, or aluminium baler—is a significant decision. Partner with a manufacturer that offers a wide range of solutions, has proven expertise, and stands behind its products.

NKBALER, as a specialist with nearly two decades in designing and manufacturing environmental protection equipment, offers a complete portfolio. From occupancy paper baler machines and used clothes balers to industrial cardboard balers and scrap plastic baler presses, they provide tailored solutions. Their machines are trusted by clients in over 60 countries across North America, Europe, Asia, and the Middle East, achieving a remarkable 99% customer recognition rate.

An NKBALER Textile Clothes Baler efficiently compacting fabric waste for recycling.

Before finalizing your purchase, request a quote, ask for customer references, and if possible, see a machine demonstration. A reliable supplier like NKBALER will be transparent and helpful throughout this process.

Ready to Optimize Your Waste Handling?

Contact the experts at NKBALER today for a personalized consultation. Discuss your specific needs for a waste paper hydraulic baler machine, MSW baler, or any other baling press solution.

Phone/WhatsApp: +8615021631102

Email: nk@nkbaler.com | Nickbaler888@gmail.com

Website: https://www.nkbaler.com

Address: East Qunsheng Road, Wuxi City, Jiangsu, China